Biotoxicity, on the other hand, deals with the materials in terms of possible damage to tissue or cells. Extensive testing and inspection procedures ensure that the materials used have no negative effects on cell metabolism or growth. The safety of materials for 3D printing of medical products is tested according to European norms (EN) or international standards (ISO) , suitable materials receive certification according to DIN EN ISO standards. The US counterpart - United States Pharmacopeia - works with similar standards, but here they are called USP Class.

Certification of materials according to DIN EN ISO 10993

Materials used in additive manufacturing for medical devices are tested using DIN EN ISO 10993. The catalog of standards consists of 20 sublabels, for example DIN EN ISO 10993-5, in which materials are tested for in vitro cytotoxicity. If a material meets the strict requirements of the standards catalog, it is certified and thus approved for use in medical technology.

Certification of materials according to USP Class

The certification of materials in the USA works in a similar way to the European EN ISO standards catalog. However, the US system works with a division into classes. USP Class 1 is the loosest class, USP Class 6 the strictest. Plastics classified in USP Class 6 offer the best possible biocompatibility. The classification of materials according to USP Class is usually seen as a minimum requirement in the field of biocompatibility. Internationally, the much stricter ISO 10993 standard is increasingly gaining acceptance.

Materials with approval according to DIN EN ISO 10993 at Jellypipe

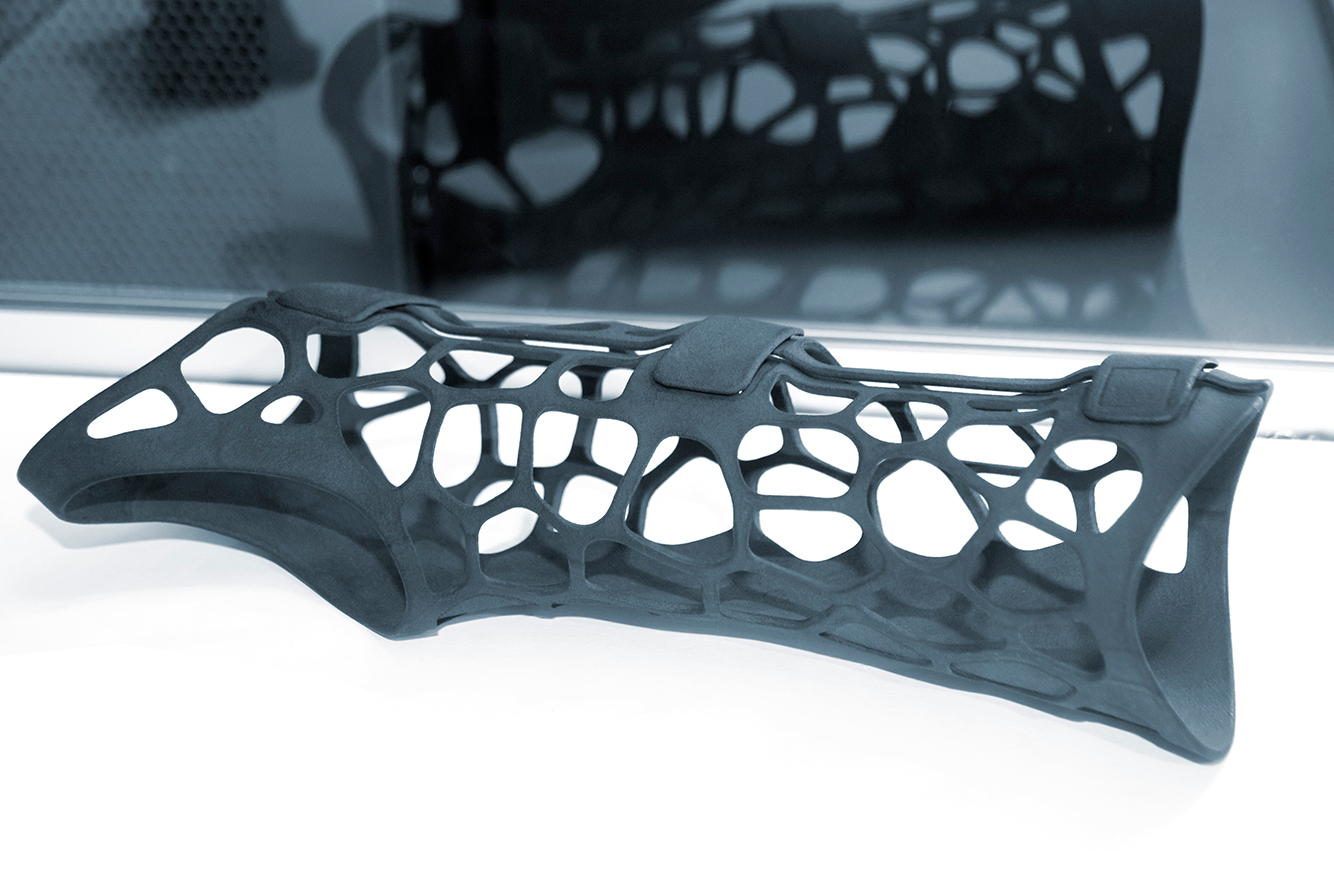

At Jellypipe, materials are available for 3D printing that are used in medical technology but are used outside the body. Approval according to DIN EN ISO 10993 is offered by the following materials:

- Daylight Magne Draft, technology LCD (similar to DLP): Very high strength, comparable to acrylic and polyamide.

- Daylight Magna Durable, technology LCD (similar to DLP): High impact strength and durability, parts can be bent without breaking

- PC-ISO, technology FDM: Et0-sterilizable, high heat resistance

- Polyamide PA11, Technolgie SAF:Good heat resistance, besides ISO 10993 also UL94 HB certified (flammability)

- ULTEM 1010, Technolgie FDM: High performance thermoplastic with good chemical resistance. Certification also according to NSF 51 (food contact), as well as UL94-V0 (flammability), heat resistant up to 216° Celsius