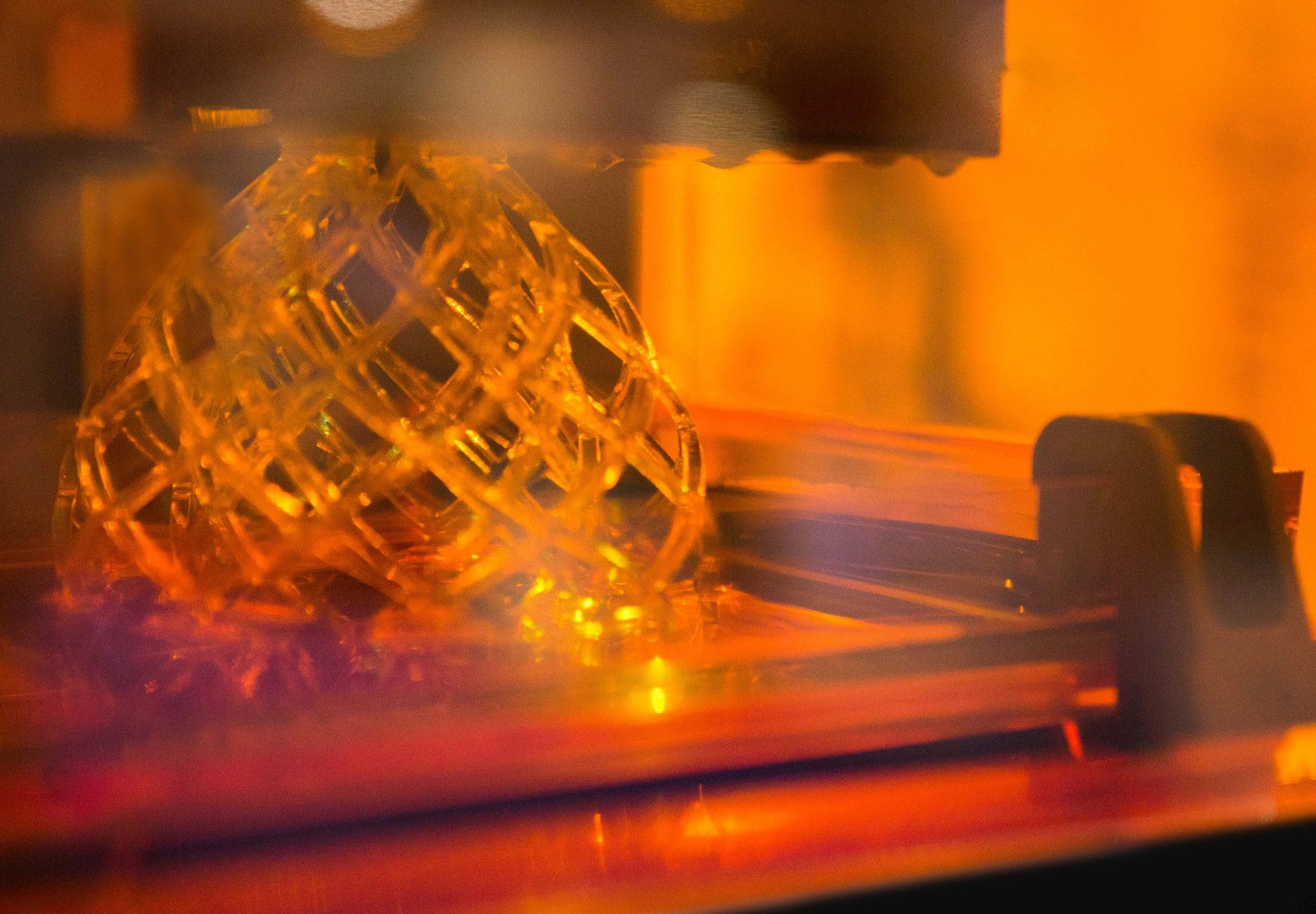

In stereolithography (SLA), the manufacturing process takes place in a basin with a movable print bed and liquid resin, the photopolymer. Initially the print bed is only covered with a thin layer of the plastic. A laser beam (UV light) is used to project the shape of the desired components onto the material. The plastic solidifies after a short exposure time, the print bed is moved down a little and the next layer of photopolymer is solidified. In order to print overhanging structures in this 3D printing process, so that parts do not simply sink into the liquid polymer bed, support structures must also be printed. There are also printers that work in the opposite direction and harden the plastic piece by piece from below.

After the components have been produced, the support structures are removed and the components are post-cured under UV light in an exposure chamber. If required, the components can then be ground, painted and/or polished.

With stereolithography (SLA), highly transparent components can be produced as is possible with almost no other technology: Material ClearVue transparent.