Additive manufacturing for a wide range of industries

3D printing for the technical industry

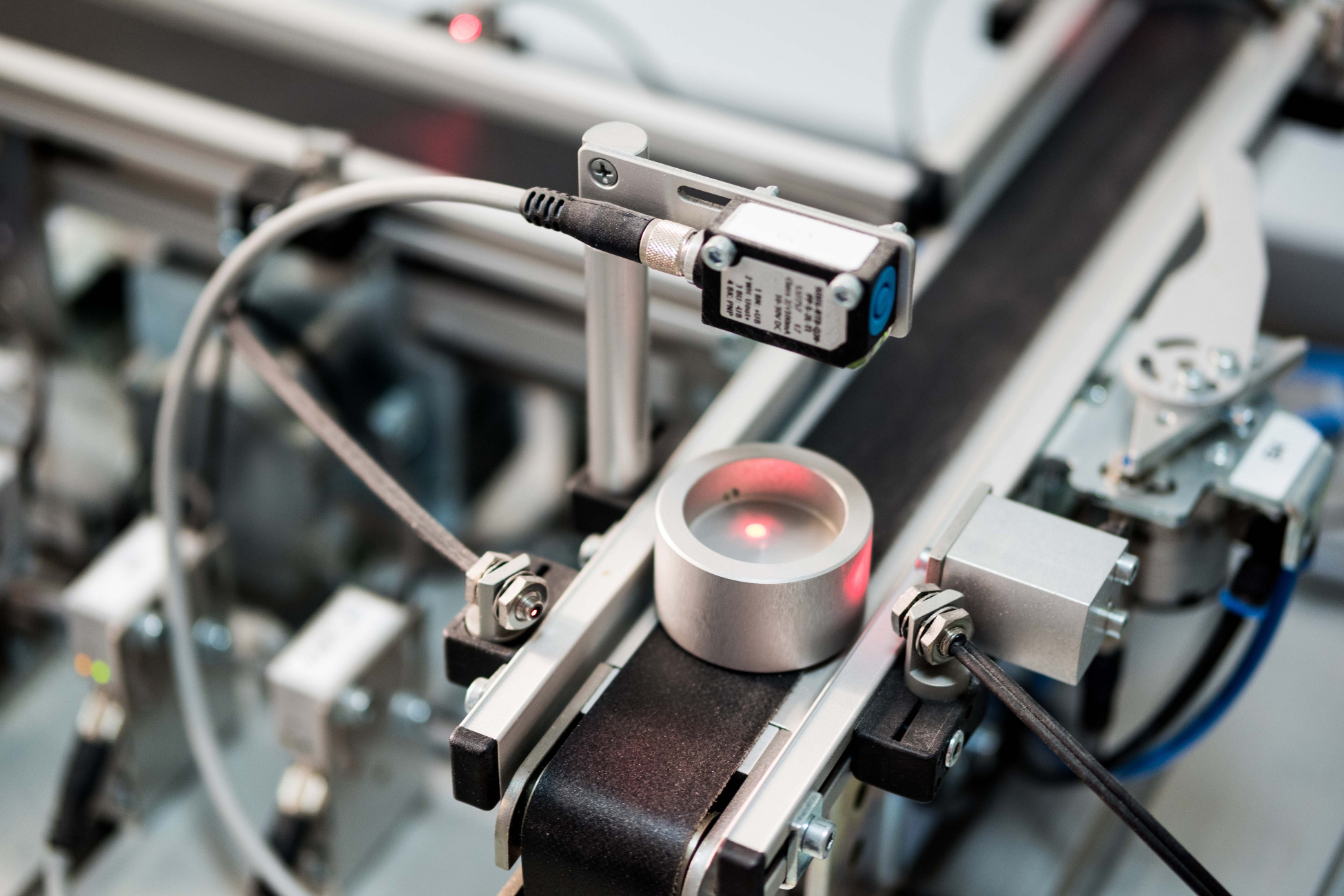

Additive manufacturing offers great potential for the use of components in machines and systems as well as for the production of operating equipment and assembly aids. Does your company produce sensors, pumps, conveyor systems or measuring devices? Or are you active in the electrical engineering sector or the energy industry? Take advantage of the potential of 3D printing and optimise your components and work equipment. At Jellypipe, you also have a large selection of materials at your disposal, so that a wide range of applications can be covered.