The Polyjet 3D printing process or Multi Jet Modelling (MJM) uses a print head with multiple nozzles to apply small droplets of material onto a printing plate. The liquid polymer is immediately hardened by UV light allowing the desired components to be produced layer by layer. As the droplets that are applied are very small, very fine details can be reproduced. Additionally the material melts before the curing process and the surface becomes very smooth. During printing overhanging components must be provided with support structures.

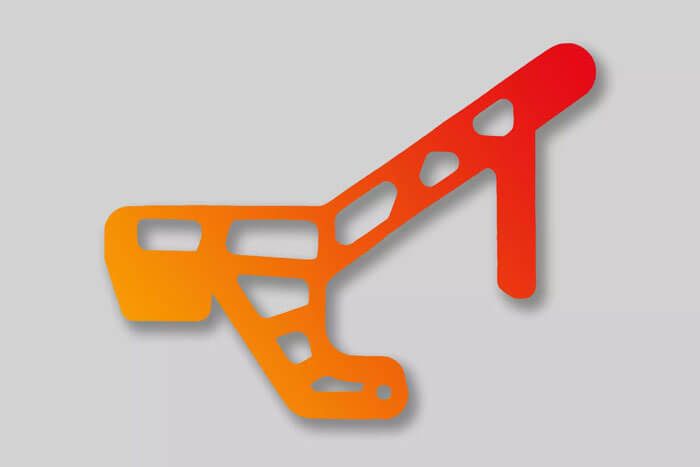

With the MJM 3D printing process, the desired parts can be printed directly in multiple colours when using multiple print heads. Translucent materials that allow light to pass through are also available. Due to the material application through small droplets, material and colour gradients are also possible.