Installation space

Quartz sand: 1000 x 1800 x 700 mm

PMMA materials (acrylic glass): 850 x 450 x 480 mm

Applications

Quartz sand:

- Toolmaking

- Illustrative models

- Mould making, e.g. injection moulds for metals etc.

- Design and decoration

PMMA materials:

- For large components

- Mould and fixture construction

- Prototyping

- For thin wall thicknesses for applications with light sources (the materials are translucent)

Advantages

- Economic production

- For large components

The Binder Jetting process

Binder jetting is a 3D printing process in which the material, e.g. quartz sand, PMMA materials or metals, is bonded in layers by a binder. In the additive manufacturing process, the printer applies a thin layer of the material powder, which is then bonded in the desired places by a liquid - a binder. After that another layer of material is applied. The components will be created layer by layer. After the printing process, the construction space will be hardened and cooled down.

When Binder Jetting is used for metals, the components are sintered after the printing process.

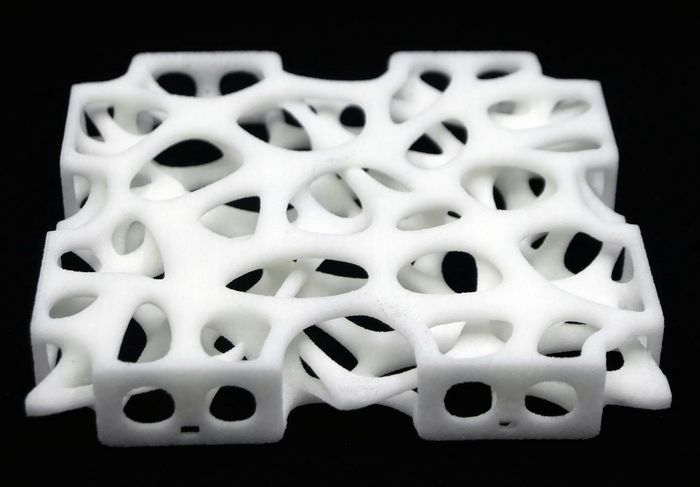

Design of 3D printed parts for binder jetting

The following points must be taken into account when designing a part for Binder Jetting:

- Minimum wall thickness: 5mm

- Lettering and surface details: min. 1 mm

- Minimum diameter of holes: 3 mm

- Tolerances: ISO 2768-m (but strongly depending on geometry and material).

- In the case of very small bores, long channels and small cavities, complete powder removal cannot be guaranteed.

- In closed cavities, the powder remains in the component. If powder is to be removed, drill a 30 mm hole.

- Components are aligned to optimise installation space

- For special requirements, please make an "individual enquiry".

Applications and finishing, quartz sand:

The finished product of quartz sand can be used in an untreated state for (metal) casting moulds or for design objects used indoors. A transparent coating makes the objects water-repellent. Coloured coatings (spray painting) in various colours are also available on request.

Applications and finishing, PMMA materials:

The materials can be coloured, lacquered or chemically smoothed. With thin wall thicknesses, these are translucent