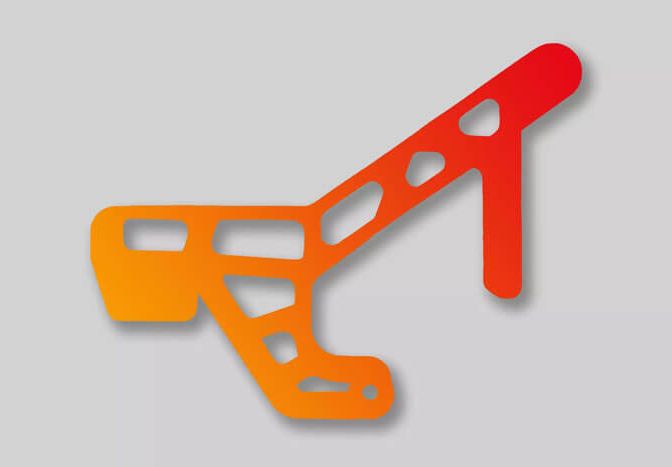

Multi Jet Fusion (MJF) is a 3D printing technology process based on the fusion of powder layers. The plastic powder is applied step by step in thin layers. Each layer is fused at the appropriate points by a print head ("fusing agent") that applies a heat-conducting liquid. To ensure that the layers are formed precisely, an insulating liquid is applied alongside the heat-conducting liquid to delineate the powder. No support structures are needed with this technology allowing the printing of complex geometries.

The MJF process is complex, but also one of the fastest 3D printing technologies. Additionally the components are waterproof and almost isotropic, i.e. the strength is the same in every tensile direction. The resolution during printing is very high, which results in a good surface quality. For multi-coloured parts, the colour information is directly included in the 3D print file.

If you are not sure whether MJF or SLS is a better fit for your project, read on here: MJF or SLS