During analysis, whether a purchase of a 3D printer is worthwhile or not, the following topics must should be considered, among many others too:

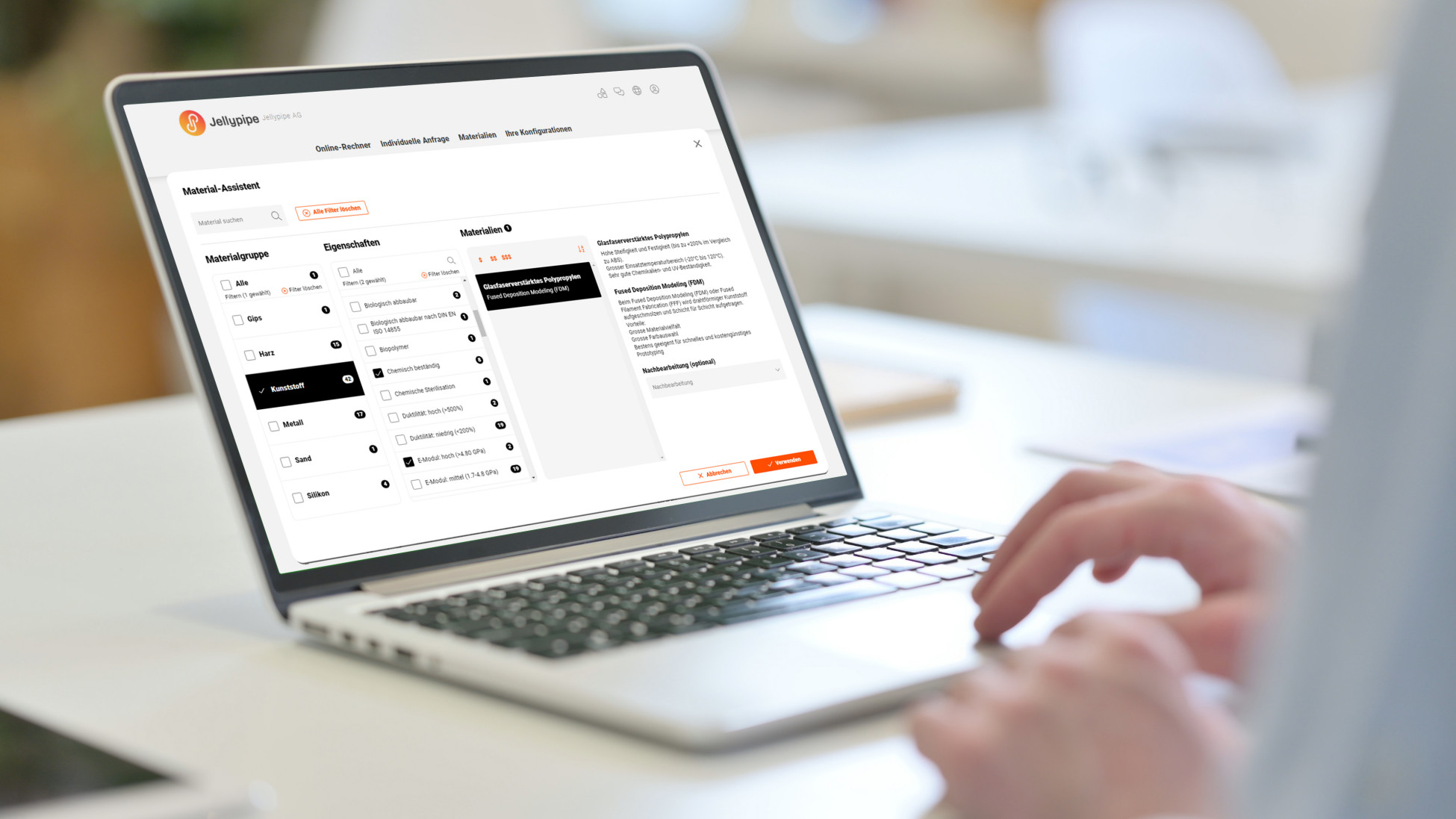

- What technology/material do you need?

- Which 3D printer is suitable and how big is the investment?

- What are the operating costs?

- How quickly and professionally is the support-service of a printer in case of a problem during printing you cannot solve by your own?

- Do you need the full capacity the considered 3D printer could produce? I.e., do you need a large number of components of a single technology? Or do you need different technologies and materials?

- How many parts must be printed until you achieve the return on investment?

- How long does it take for an employee of your company to become familiar with the technology and produce usable components in the quality needed?

- How fast is the technology developing? I.e., will a printer with significantly higher efficiency be sold on the market in just a few months?

Such an analysis will often show - especially for smaller or medium-sized companies - that the investment is very high, and it needs some time, until usable parts can be printed. An advantage of manufacturing in-house is that parts are available immediately after printing, and you will build up knowledge about the whole process.

A disadvantage is the limitation in terms of materials that can be printed on one printer. There is also the high risk that the technology will become obsolete before the investment has paid off. With a new technology developing at breakneck speed, this is an important aspect that should not be ignored.