How to start your project!

Surely now you think of a project you have? This is how you start.

The simplest variant: You discuss a concrete project with your contact person (Solution Partner of Jellypipe (7)). Based on the area of application and properties of a component, you will receive answers as to what needs to be considered in the design.

Another approach:

1. inform about basics

Familiarize yourself with the appropriate process. First inform yourself about basic topics. How an FDM print works; similar to a 2D printer, but with layers, you can imagine. Powder bed processes are quite different. Watch a video of a 3D printer using powder bedding processes, e.g. SLS (8), to get a first impression of what happens during production. After that, learn about basic design topics such as topology optimization (9) and lattice structures (10).

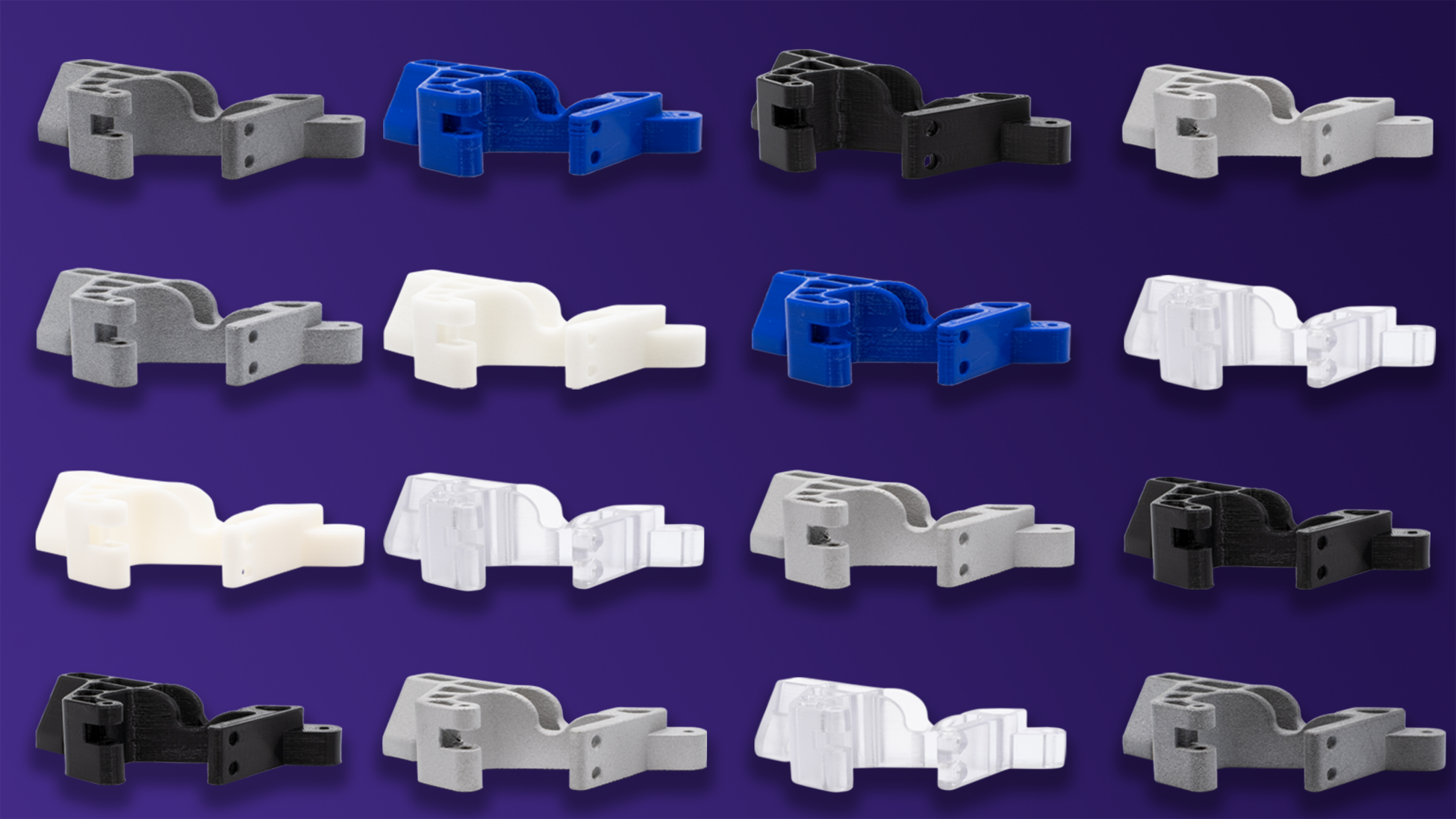

2. choose material and technology

Next, select the appropriate material for your component. Define properties and application area, and narrow down the material. The easiest way to do this is with the material wizard on the platform. Are you unsure? Just ask!

Based on the selected material, you will be taken to the available processing technologies. At this point, it makes sense for 3D printing beginners to check whether the chosen material/technology combination makes sense. Ask your solution partner! Afterwards, nothing stands in the way of the design and a successful project!

3. consider technology-specific peculiarities, design component

The technology used now defines the basis for your design, i.e. the 3D printing design guidelines for your project:

- If there is more than one technology to choose from, read more about the differences (11a, 11b, 11c).

- What are the minimum wall thicknesses required for the selected technology? (12)

- Are support structures required for the chosen technology (13)i.e. angles and overhanging parts must be optimally designed accordingly.

- What about surface finish (3b), is it necessary to plan for post-processing, if so where and which?

- Can/should corners/edges be mapped, or is it worth designing them as curves?

- Can the part be printed hollow or do holes need to be drilled for powder removal?

- Are threads required, do they have to be cut subsequently or are thread inserts used?

- Do certain chemical resistances have to be met?

- Are certain certifications required?

Design ready? Congratulations, now you can order your first component!

4. order component or get offer

If you are already sure what you need, you can order your component directly. Is it the first of its kind? You are also welcome to make a so-called "individual request" on the platform, if there are still uncertainties. The Print-Factory will then check the project and give you hints and prepare an offer.

We are looking forward to your project. If you have any questions, please do not hesitate to contact us or our solution partners.

Your Jellypipe