Designing a topology optimised 3d print component is achieved easier with appropriate cad software

To achieve an optimised topology, it is important to know all properties a component requires in detail. This avoids design faults. For a simple version, the optimisation of a component can be done manually. To an engineer, it is obvious where the geometry of a part should be optimised, when there are almost no limits in the manufacturing process as in 3D printing compared to conventional methods. However, if the component is to be optimised perfectly and quickly, it is vital to use suitable software.

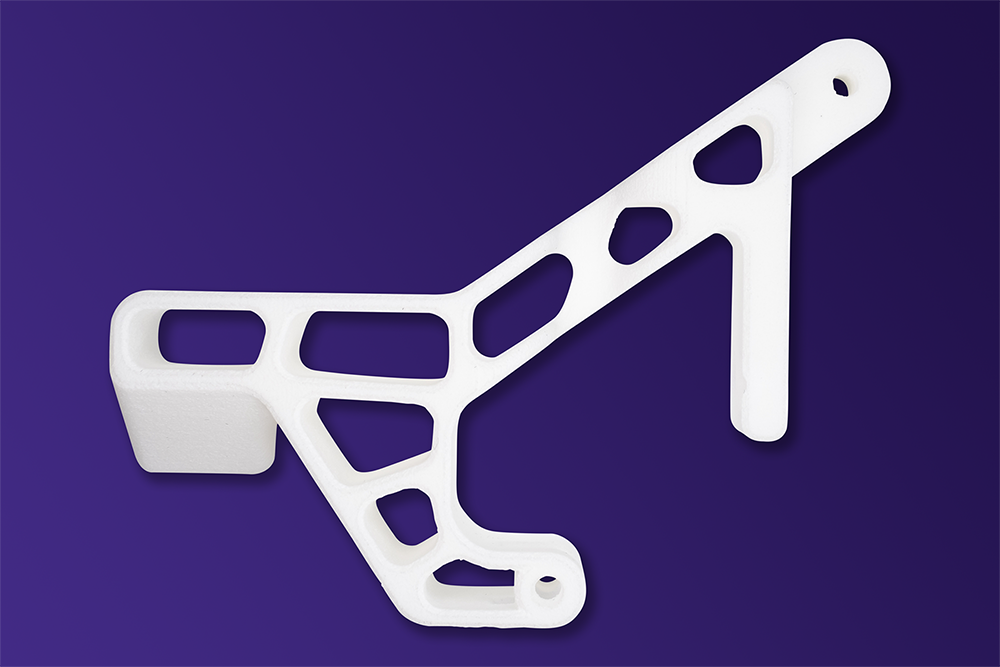

In topology optimisation software, the algorithm calculates the stress and deformation of a component under load. Numerical methods are used for this, for example the finite element method (FEM), which divides the shape of a component into many cuboids and tetrahedra to calculate the physical properties. From the original component, a fissured, porous model is first designed, a kind of bone structure that serves as a design aid. This is then optimised in several steps: The component is defined by simulating the load cases, i.e., where, in which strength and direction force and tension act. The areas under heavy load contain material. In areas that are not under tension, the material is omitted. This creates components with cavities, openings, or honeycomb structures.

The most important optimisations are the following:

- Interfaces to other components

- Connecting components

- Avoiding abrupt transitions and sharp edges through curves

- Suitable filling structures such as honeycombs

- Organic structures and shapes for optimal power transmission