Can it be a little more robust and stable?

In conventional manufacturing, every material used has very specific properties. Tensile and breaking elongation, resistance to plastic deformation or separation, or the hardness of a material are predefined and can only be extended to the natural limits. The behavior of a sheet of aluminum or steel can be defined or controlled by the alloying constituents during production and the actual processing of the material. Properties can be further optimized by bonding or mechanical connections with other materials.

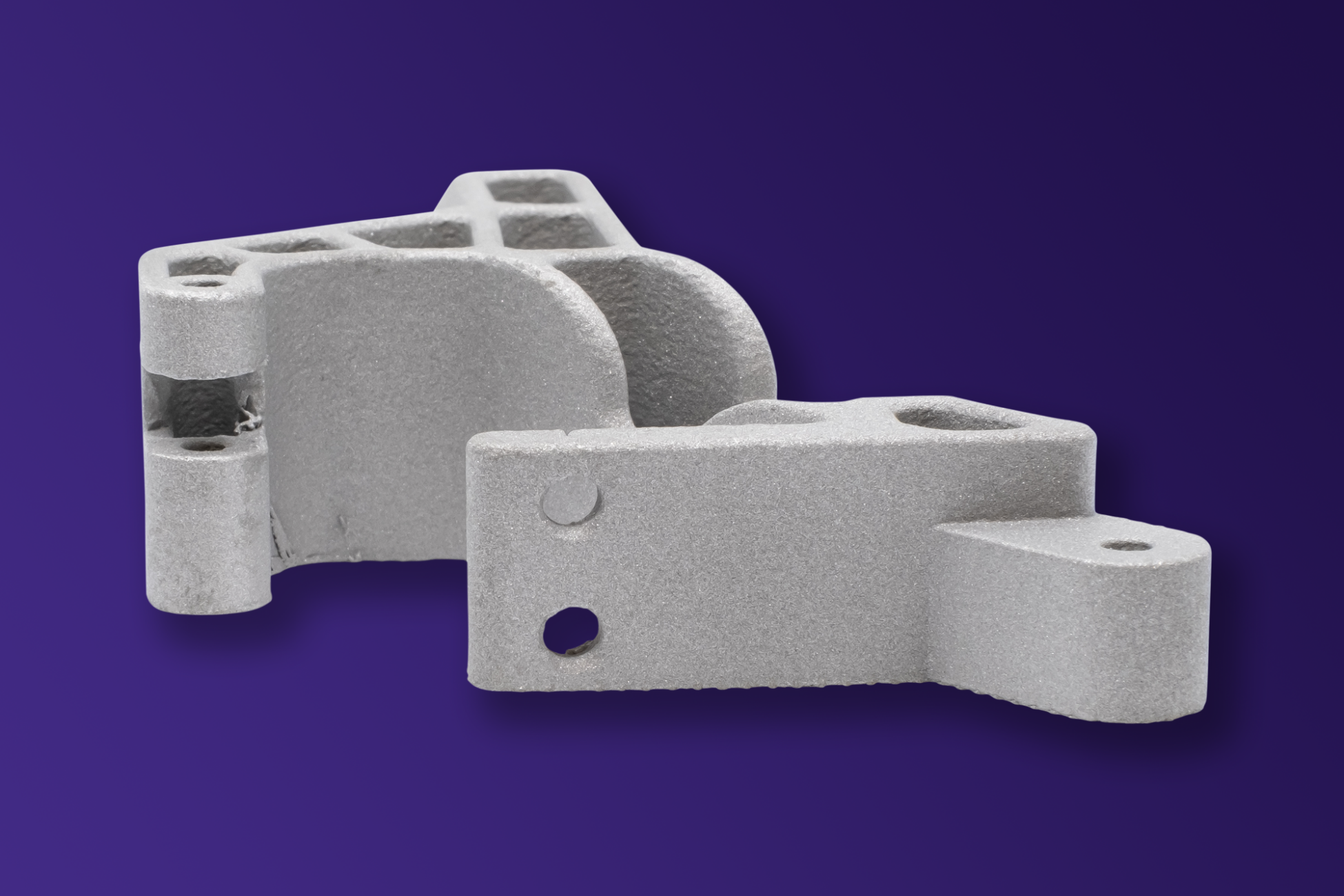

What is missing, however, are creative degrees of freedom in the design; the restrictions regarding the accessibility of tools or the demoldability from injection molds remain. This is precisely where the advantages of additive manufacturing come into play. On the one hand, laser melting makes it possible to print metallic workpieces whose density is up to 99.9% that of rolled or forged material. In addition, different materials can be combined in the 3D printer. By reinforcing with carbon fibers directly during production or inserting continuous fibers, plastics can be made even more stable, robust and, above all, precisely adapted to the respective application. And all this with absolute design freedom, which allows, for example, load-optimized internal rib structures, internal cavities, or flow channels.

Generative design: stability based on nature's example

Evolution is enormously good at implementing flow rates, thermal efficiency or vibration reduction - even better than human technology is capable of. With ever-increasing computing power and advances in artificial intelligence, it is now possible to come close to nature's models in the field of additive manufacturing. 3D printing allows the design of previously traditionally manufactured components to be adapted in such a way that not only can the components be produced much more efficiently and with much less waste, but performance, stability and robustness are also significantly increased.

Automated calculations in the CAD environment thus create near-natural, almost organic-looking shapes - a copy of nature, which is known to "engineer" to perfection. Generative design allows the production of parts that are once again significantly more stable than comparable workpieces produced using conventional 3D printing, while keeping weight to a maximum.

3D printing design with lattice structures

Lattice structures, for example, currently offer an excellent opportunity to completely redesign components that were previously manufactured in solid material. Less weight, lower costs and yet maximum stability: lightweight structural design is undoubtedly an area that offers many and completely new design possibilities thanks to modern additive manufacturing processes. Read more about it in our blog: Lattice Structures

Conclusion: prejudice debunked!

Parts from the 3D printer look good, but cannot compete with conventionally manufactured components in terms of stability and robustness: For years, this prejudice has run through the conversations that arise around the topic of 3D printing processes. In the early years of additive manufacturing, this prejudice may have been true - state-of-the-art 3D printing processes, however, are throwing the prejudice where it belongs: on the discard pile of outdated views.

In particular, 3D printed parts from the powder bed are completely comparable to conventional components in terms of both stability and robustness. Moreover, through the clever combination of materials and printing processes, all components can be adapted quite precisely to their intended use. With constantly expanding computing power and the use of artificial intelligence, generative design is also made possible - which is based directly on nature's perfect "constructions" and thus maximizes the stability-to-weight ratio.

Do you have any questions about the potential applications of additive manufacturing in combination with industrial plastics or metals, or would you like to discuss a specific project with us? Then the best thing to do is to get in touch with us right away!

Your Jellypipe