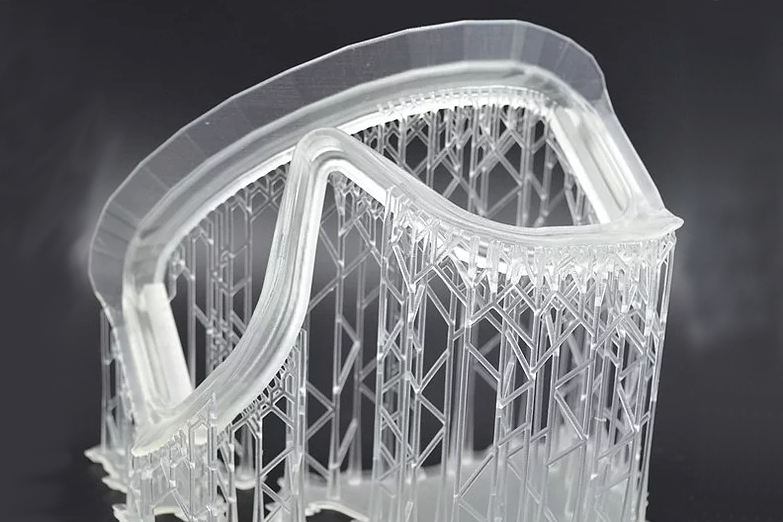

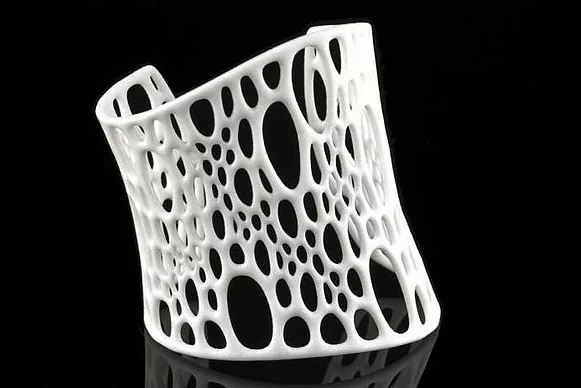

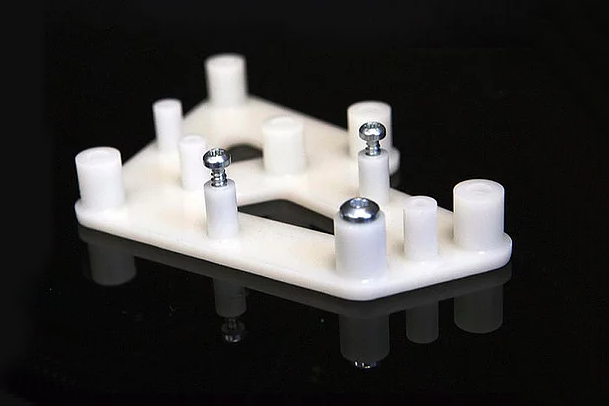

3DM Tough (DLP), RR60 crystal clear (SLA) and ClearVue (SLA) in comparison

Excursus: Differences between translucent and transparent 3D printing materials

The 3DM Tough (DLP) and RR60 crystal clear (SLA) materials are both translucent. The 3DM Tough also has the property that it does not yellow even after a long time. Furthermore, it is the least expensive of the translucent materials for DLP and SLA. The ClearVue Transparent 3D printing material from SLA technology, which has been available on the platform for some time, is much more transparent (clearer) than the two new materials. However, ClearVue Transparent only achieves this clarity through specific, complex post-processing and is therefore also the most expensive in this category. When selecting a suitable material, the technically required properties must be taken into account.

In the construction of transparent or translucent materials, the wall thicknesses also have a decisive influence on the transparency of the parts. In general, the thinner the wall thickness (observe minimum wall thickness for SLA and DLP 0.3 mm), the more transparent.