Requirements not mentioned can make a 3D printed part unusable

Since many customers are not yet well versed in 3D printing, the risk to a project from requirements not mentioned is great. If you know the desired technology-material combination and are familiar with 3D printed part design, you can easily order your parts through a Jellypipe store in the configurator.

If you are unsure, we need all the details to understand exactly how and where the part will be used later. This is necessary so that we can recommend a suitable material-technology combination:

- Quantity: Is a single part needed or is a series planned (may have an influence on the choice of technology).

- Properties: What is important, necessary, e.g. chemical resistance, high accuracy on a surface, a specific color

- Environmental conditions: Will the part be exposed to strong pressure, great heat/cold, or weather?

- Material / technology: what is desired, if you already have an idea of it

- Data: Component, image, CAD files, a 3D print file, include everything available.

- Additional information: Mention everything that is important for the use of the component or for the project.

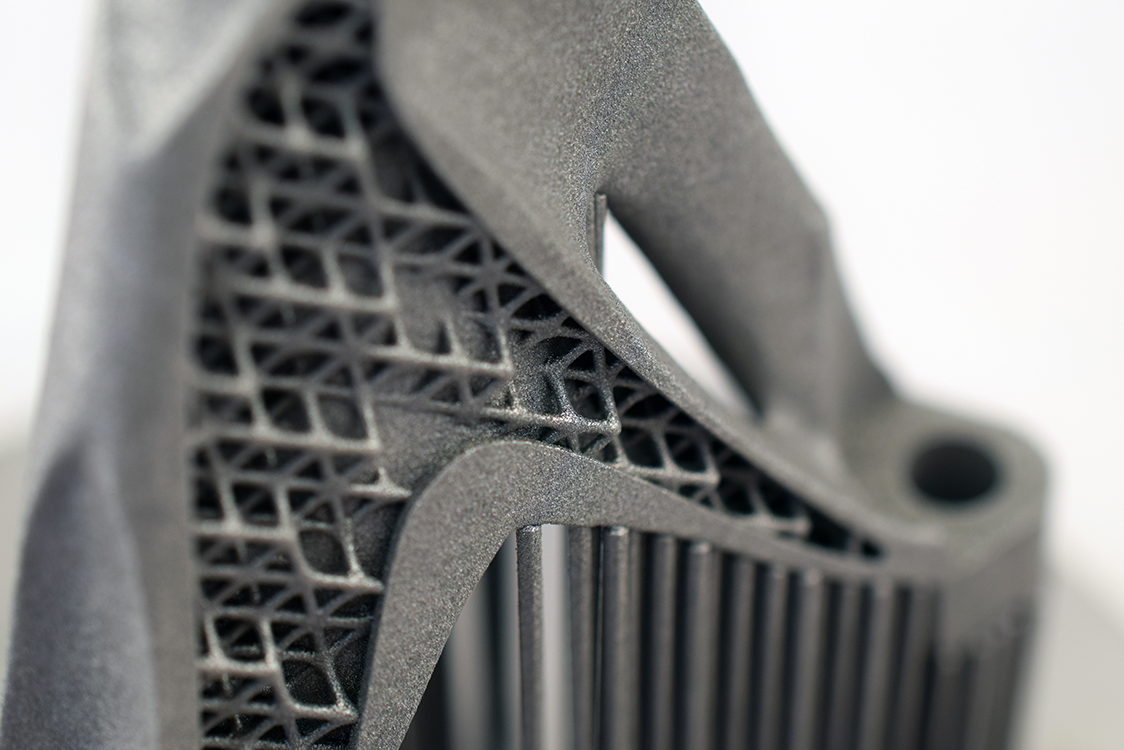

In addition, for metal 3D printing orders, we recommend always making an individual request for larger quantities or volumes. Additive manufacturing of metals is much more demanding than plastics.

If you provide the above information, your project will also be a success.