Technology type

Installation space

- 100 x 100 x 100 mm

- Larger applications are possible, but depend on the design

Applications

Depending on the material used:

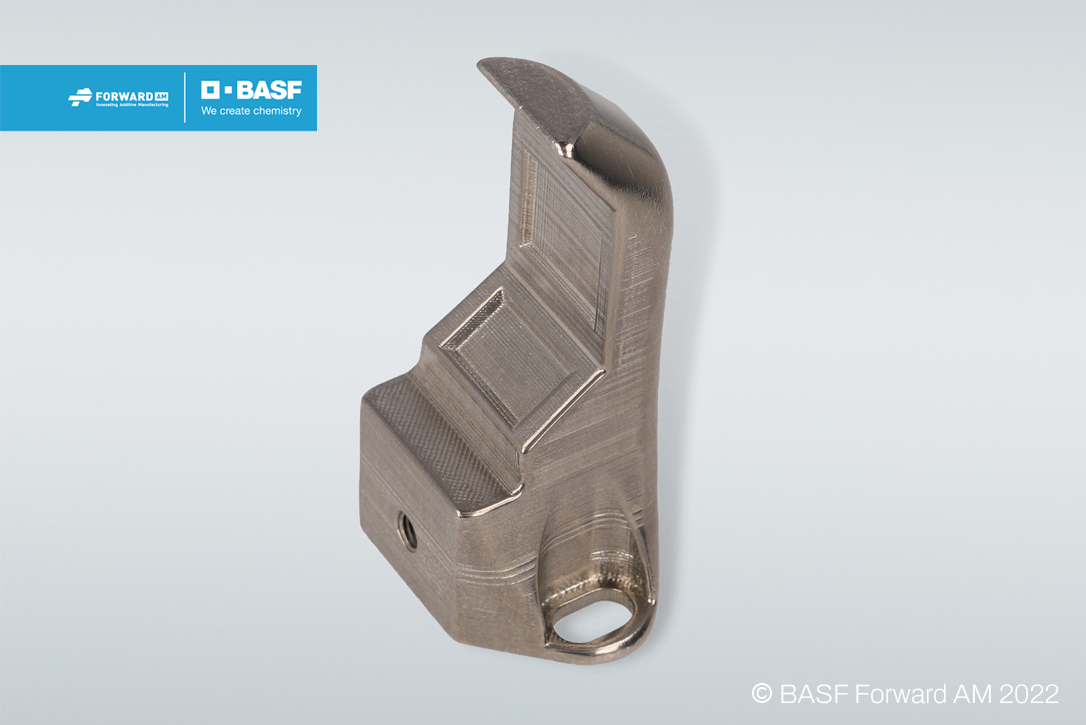

- Machine parts

- Pipe connections

- Spare parts

- Tools, fixtures and holders

Advantages

- Metal parts from the FDM process are up to 50% cheaper than from the SLM process

The process:

FDM metal 3D printing works like the FDM process for plastics in the first step. The filament is fed to the hot end via an extruder. There it is melted down and then applied to a print bed via a nozzle in the desired geometry defined by the CAD file. Layer by layer, the metal component is created in the workspace.

The filament material, Ultrafuse®, consists of metal powder held together with polyoxymethylene (POM) binders.

When 3D printing is complete, the so-called "green part" is created. The green part largely corresponds to the later finished part, but still contains the binders, which must be removed in the next step. The "debinding" is carried out in highly automated furnaces by means of catalytic acid vaporization. During the process, about 90% of the binder is removed and the component loses about 10.5% of its weight. The result of debinding is the "brown part".

The brown part now undergoes another production step: sintering. During sintering, the material is compressed by heat or pressure and formed into a solid mass of material. In this process, the sintering temperature is always below the melting temperature of the metal used so that it does not liquefy. The process starts at 250°C and is completed at 600°. The brown part shrinks by another 16% in the X and Y axes, and by 20% in the Z axis.

After sintering, the metal part is finished. Then, depending on the application, it can be further finished by bead blasting and polishing.

Design for FDM metal 3D printing:

You can find design notes here: Design for FDM Metal 3D Printing