What are you looking for?

- Binder Jetting (BJ)

- Digital Light Processing (DLP)

- Direct Metal Printing (DMP)

- Fused Deposition Modeling (FDM) plastic

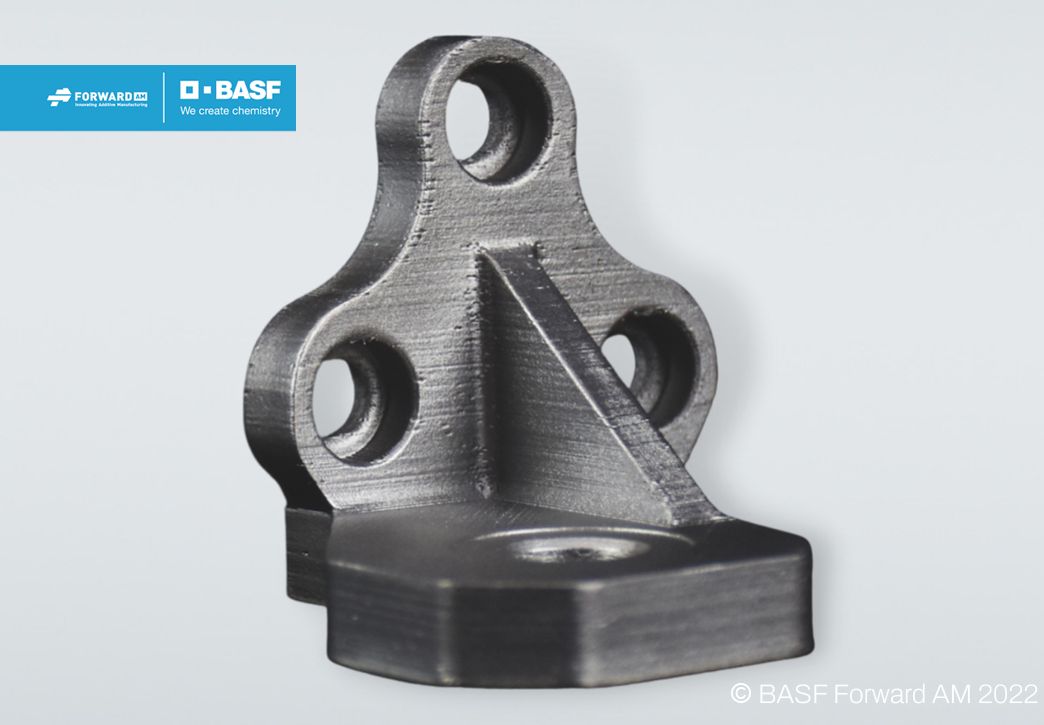

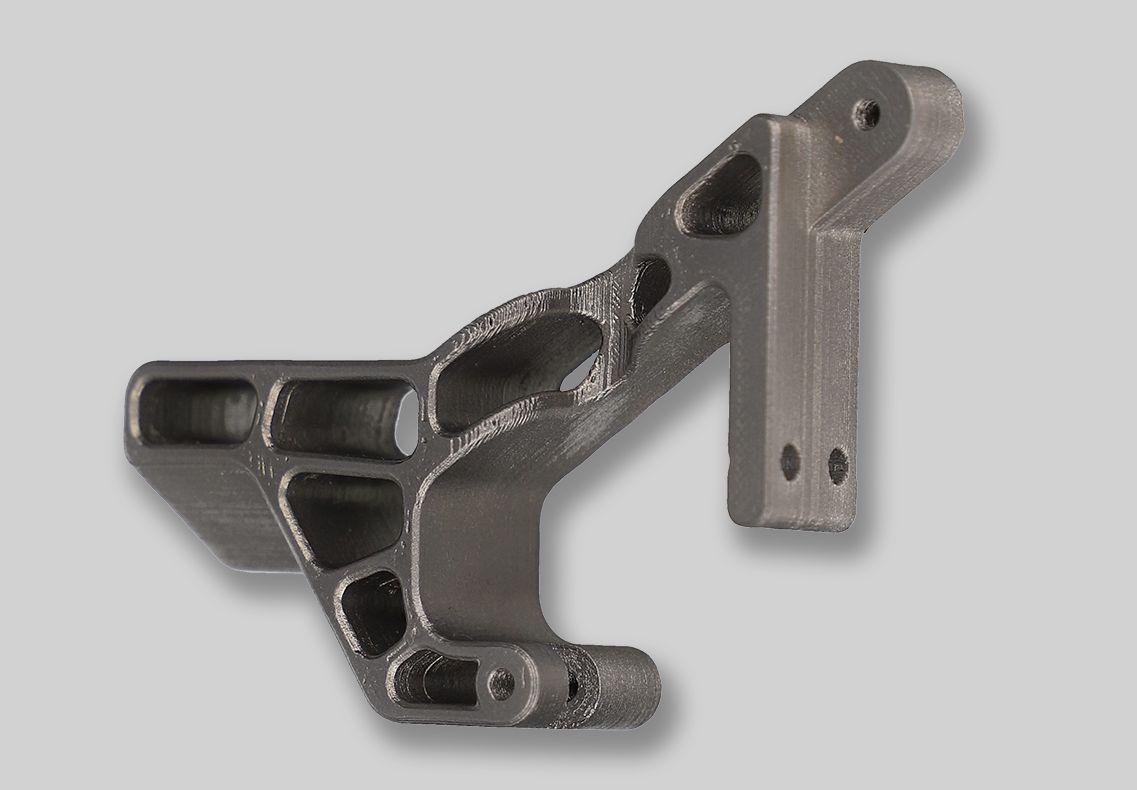

- Fused Deposition Modeling (FDM) metal

- Investment casting

- Multi Jet Fusion (MJF)

- Multi Jet Modeling (MJM)

- Selective Absorption Fusion (SAF)

- Selective Laser Melting (SLM)

- Selective Laser Sintering (SLS)

- Stereolithography SLA

- Vacuum Casting (VC)