You would probably have the perfect answer as to how much it costs. Unfortunately, this is not possible in general, as there are too many factors driving costs in the additive manufacturing of aluminium and other metals.

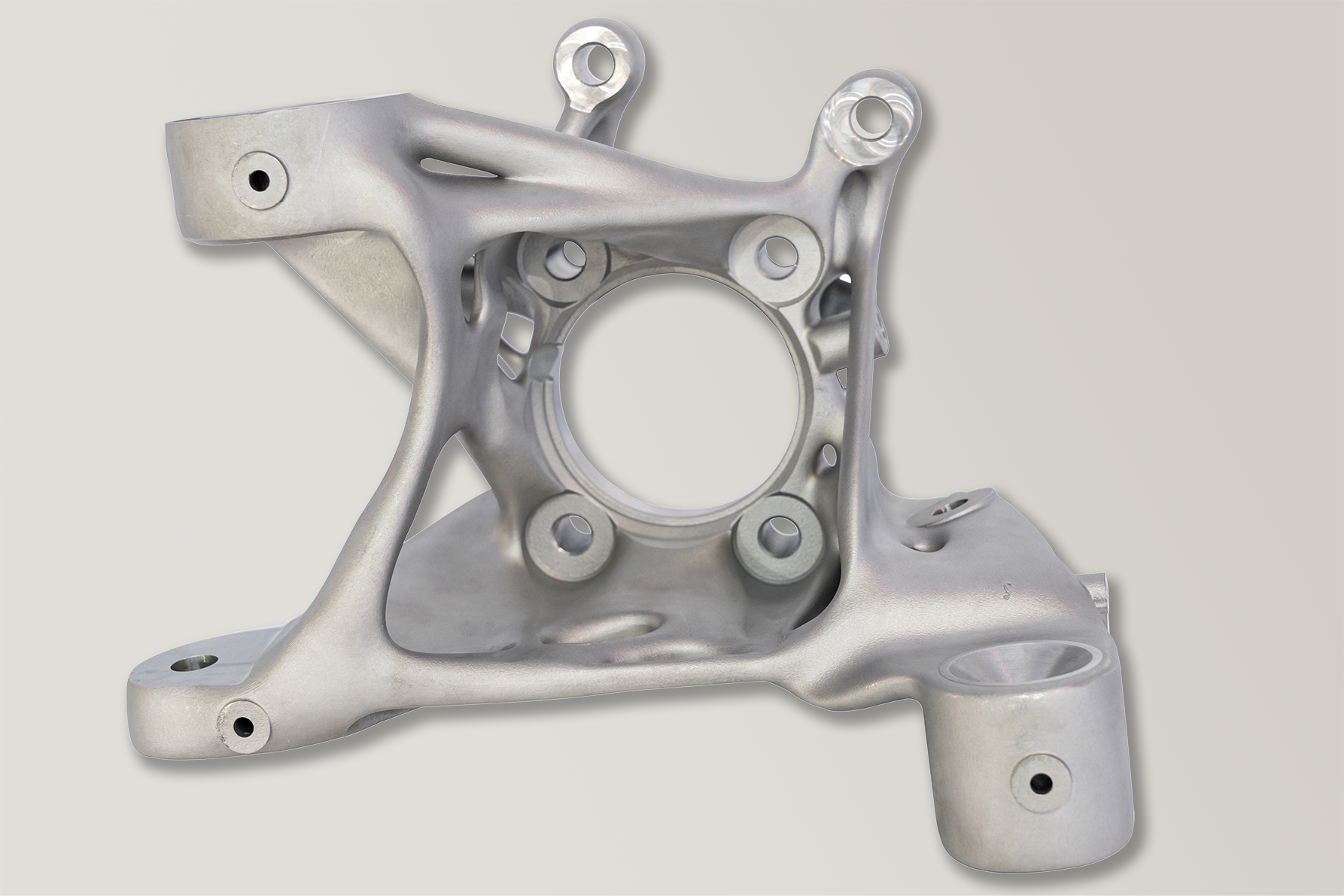

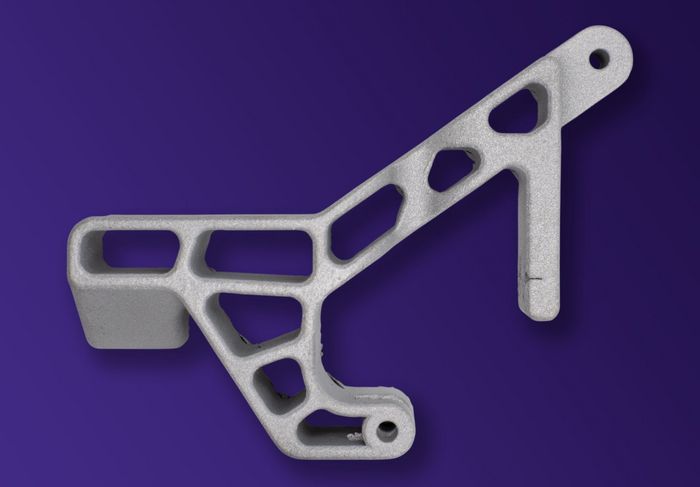

The following facts are relevant: If a conventional produced metal component is manufactured 1:1 in 3D printing, the costs are usually higher. This is because metal 3D printers are very expensive to purchase and the material, the powder is expensive too. In addition, a complex process is required for processing. Furthermore it has an impact how much space a component takes up in the installation space of the printer, e.g. for honeycomb structures.

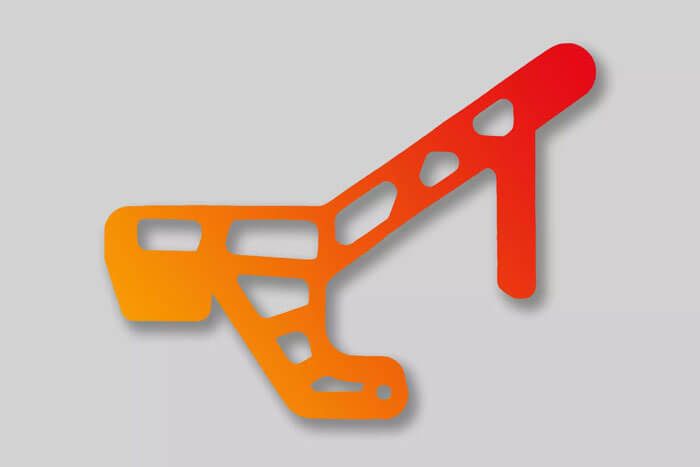

If parts can be designed optmized regarding to their application due to the freedoms in additive manufacturing, the additive technology is worthwhile. The same applies when parts are produced in small quantities or cannot be produced in any other way.

If you would like to check your project, talk to our experts. We will be happy to evaluate the perfect solution together with you. There is a choice of SLM or FDM technologies, FDM is cheaper in most cases.