How to create 3MF files - and how to convert STL files?

The development of the 3MF standard is supported within the consortium by well-known manufacturers such as Dassault, HP and Autodesk. Accordingly, programs such as Solidworks from Dassault or Netfabb from Autodesk are inherently capable of creating 3MF files. It is also possible to open and edit a 3MF file with Microsoft's 3D Builder or Paint 3D. The creation of 3MF files directly from the design environment is correspondingly simple and can be realized with a few mouse clicks using the "Save as..." functions of the programs.

However, if only an STL file is available, this still has to be finalized for printing. An excellent tool - and one that is available free of charge - is Meshmixer from Autodesk (external link to Meshmixer page). The "Swiss Army Knife," the developers' own term for the solution, can not only optimize the triangular meshes of STL designs, but also enrich the model with a wealth of additional information. And, of course, at the end of the design process, save everything in 3MF format. Of course, the reverse also works: converting a 3MF file into STL is possible at any time with the solutions mentioned.

Also on the Internet, numerous providers offer free online tools for converting STL files into 3MF format. However, we do not recommend this option - especially if the designs contain confidential information.

One file instead of many individual files - Why 3MF is so ingenious and the future

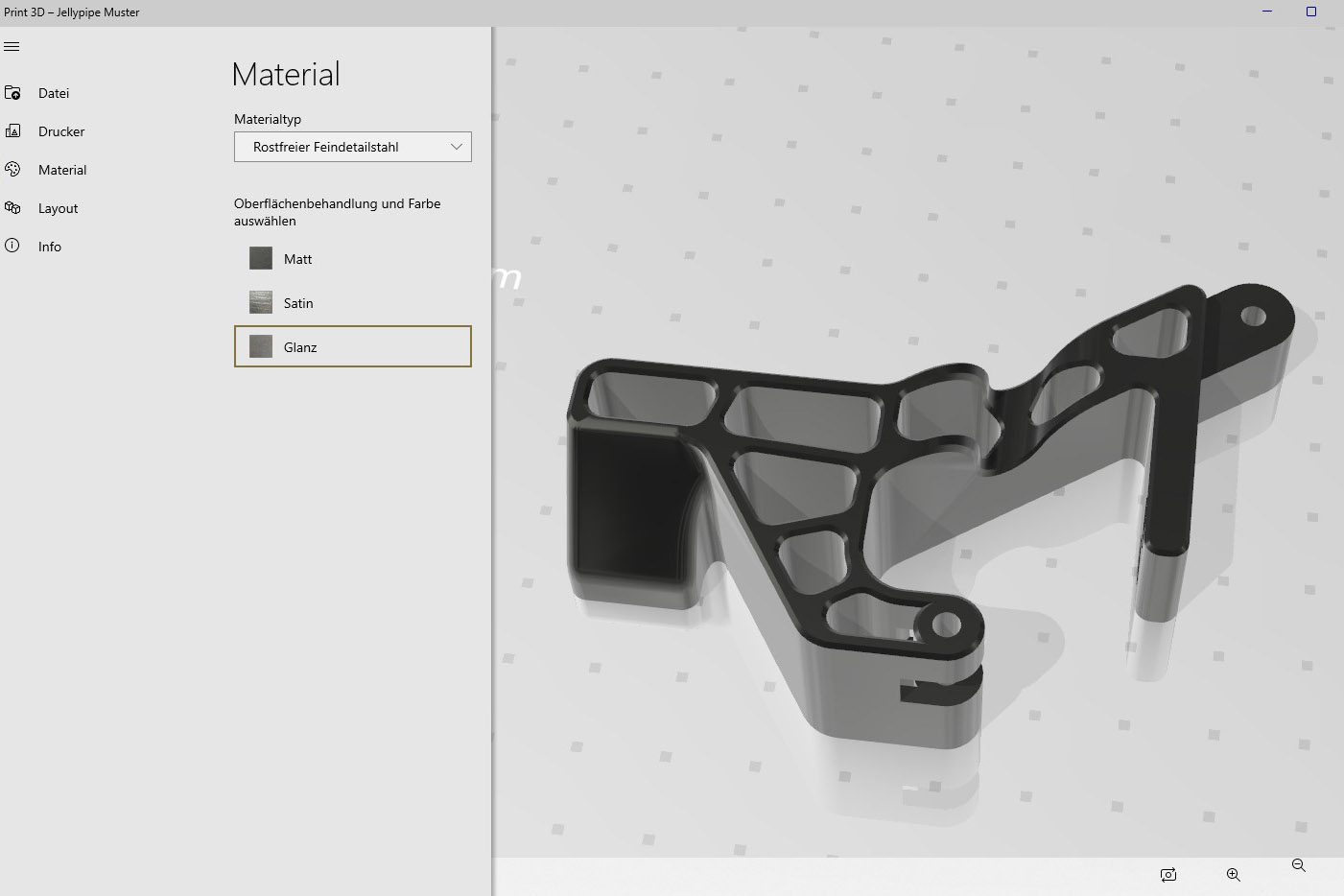

In the field of industrial manufacturing, the complexity of the required components is continuously increasing. Particularly in special sub-areas such as 3D metal printing, perfect surfaces are required - or parts are required that consist of different individual components. The "classic way" via STL files has reached the end of its capabilities here when it comes to realizing the products at external service providers. In the case of complex components, extensive enrichment of the data with additional information, for example the alignment of the workpiece in the installation space of the printer or the coloring of individual layers, has been an indispensable part of the production process up to now. The disadvantages: A complex, cost-intensive workflow with numerous potential sources of error.

3MF significantly simplifies data exchange. As in a PDF, multiple pieces of information can be bundled within the 3MF file. Assemblies consisting of different parts, each with individual coloring or its own materials, printer configurations, support structures: Everything that is needed for 3D printing in terms of information can be listed, saved and sent in the 3MF environment.

We are sure: The future belongs to the 3MF format! Almost every week, enhancements and revisions appear that adapt the solution for production, slicing or optimization of lattice structures. The cooperation of the consortium ensures that 3MF is already compatible with the programs of the renowned manufacturers in the best possible way.