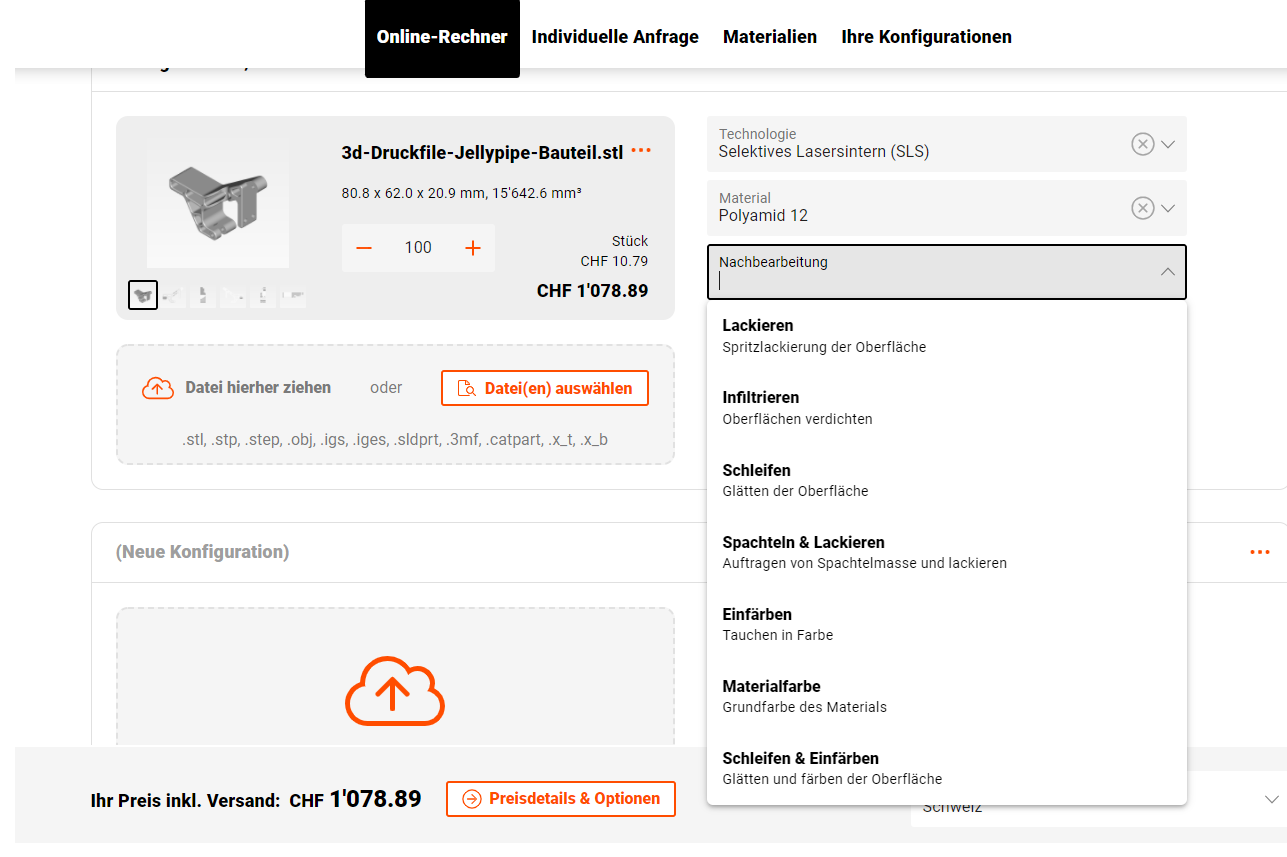

Different post-processing methods in additive manufacturing

Painting in various RAL colours

Thanks to varnishing, your 3D printed parts receive the desired surface quality and colour. You can choose between a standard lacquer finish and a high-gloss lacquer finish. The exact finish and colour are selected via the DIN-certified RAL colour. The advantages of this option include low costs and short delivery times.

Colouring 3D printed parts

On the one hand, colouring 3D components offers you all the advantages of infiltration (namely stability and dirt resistance), on the other hand, there are no limits to a visually appealing colour design of the original 3D print.

What does infiltration mean in the context of 3D printing?

Infiltration closes the surface, making your 3D printed objects more stable on the one hand and better protected from contamination on the other, as they have a higher compressive strength and waterproofness. This is made possible by infiltrating components with a specific resin.

Vibratory grinding/trovalising for a smooth surface of the additively manufactured components

The surface of sintered objects from additive manufacturing is slightly rough and porous after removal. However, this can be smoothed well with the appropriate post-treatment. Rough edges can be rounded off by vibratory grinding/trovalising especially.