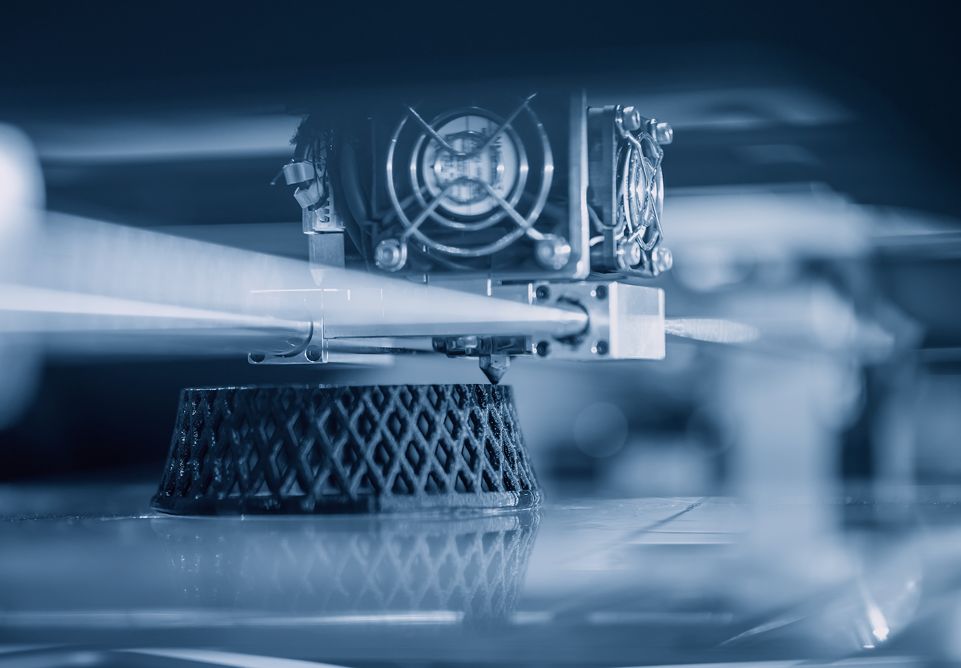

Additive manufacturing makes it possible to design assembly aids and operating equipment optimised for function and to purchase them in low quantities at attractive prices. Every production company should identify and implement suitable applications.

The topic of lean manufacturing - lean production - rightly enjoys a high priority in many production companies. 3D printing makes these projects easier and faster to implement. The requirements for operating equipment, tools and assembly aids are very different in industry and each application must be considered individually. Often it is a question of individual pieces or smaller series. 3D printing with different technologies and materials can meet these requirements and offer added value. For example, assembly aids with comparable properties but significantly lower weight can be produced. With the constructive degrees of freedom of additive manufacturing, components can be better optimised for the required function negating the limits of conventional manufacturing.

Another advantage is the high flexibility of 3D printing and the short delivery times allowing , projects to be completed and the products to be useda few days after design. This not only motivates employees for further lean manufacturing projects, but also increases efficiency in production. Another factor that should not be underestimated is the low procurement costs, especially for individual items. With conventional manufacturing, higher costs are associated with set-up and machine set-up, but with 3D printing this is not the case and allows for attractive prices.

For which tools is 3D printing suitable?

Some examples:

- Storage bins and shelves

- Containers and sorters for conveyance and transport

- Tool holder

- Templates, stencils and gauges

- Spacer

- GripperMachine parts

Not fully convinced? Start looking in your production for possible operating equipment that was produced using conventional methods such as turning and milling, but whose optimisation would bring advantages. Optimise the parts for use and order a 3D printed variant. With Jellypipe, you also choose whether a shorter delivery time or lower costs are more important - according to your needs.

Your Jellypipe