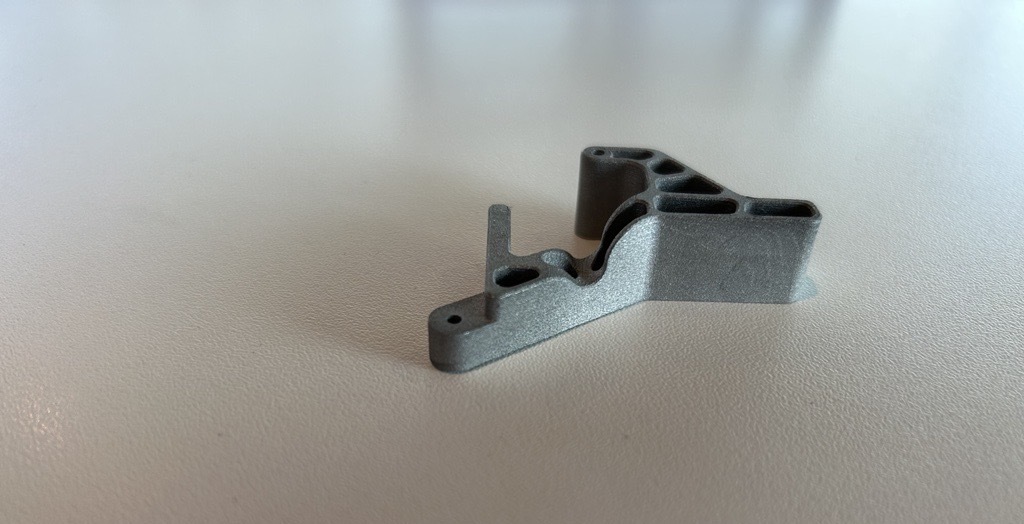

Applications for stainless steel 17-4PH

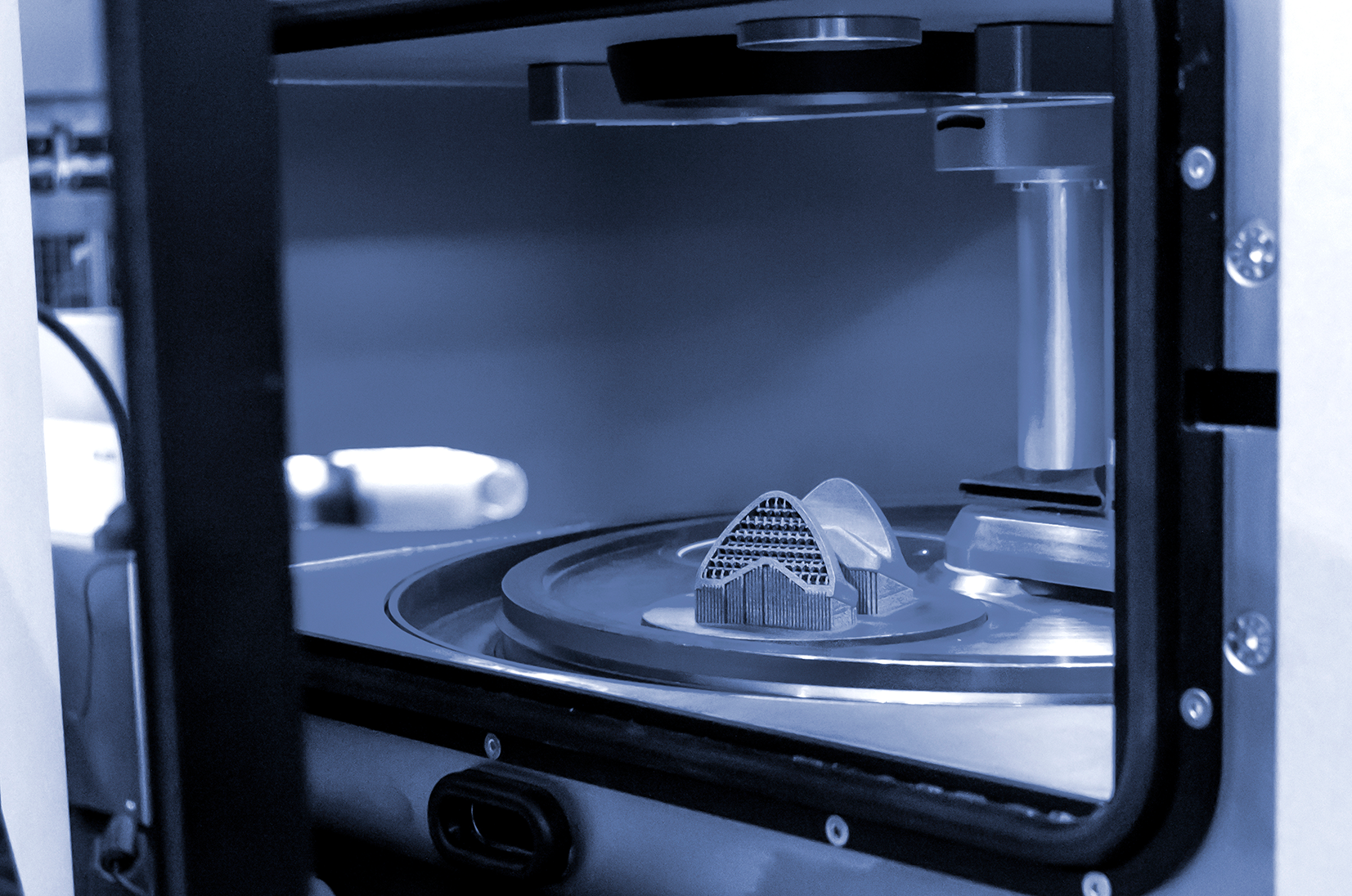

Stainless steel 17-4PH demonstrates its strength in a variety of applications. This robust material is ideal for manufacturing machine parts, spare parts, and tools. However, its potential uses go far beyond these basic applications.

Thanks to its high mechanical stability and hardness, stainless steel 17-4PH is particularly well-suited for demanding environments with exceptional requirements. In the aerospace industry, for example, high-strength components such as turbine blades and structural parts are made from this material. These components must withstand extreme temperatures and enormous mechanical stresses - no problem for stainless steel 17-4PH.

The automotive industry also finds diverse applications for stainless steel 17-4PH. It plays a key role in the production of engine components, transmission parts, and suspension components due to its high strength and durability.

In the field of medical technology, it is highly valuable due to its excellent biocompatibility and corrosion resistance. For example, it can be used in the manufacture of surgical instruments, implants, and prosthetics where both mechanical stability and resistance to bodily fluids are crucial.