Not sure which 3D printing material will fit? Find it with these steps:

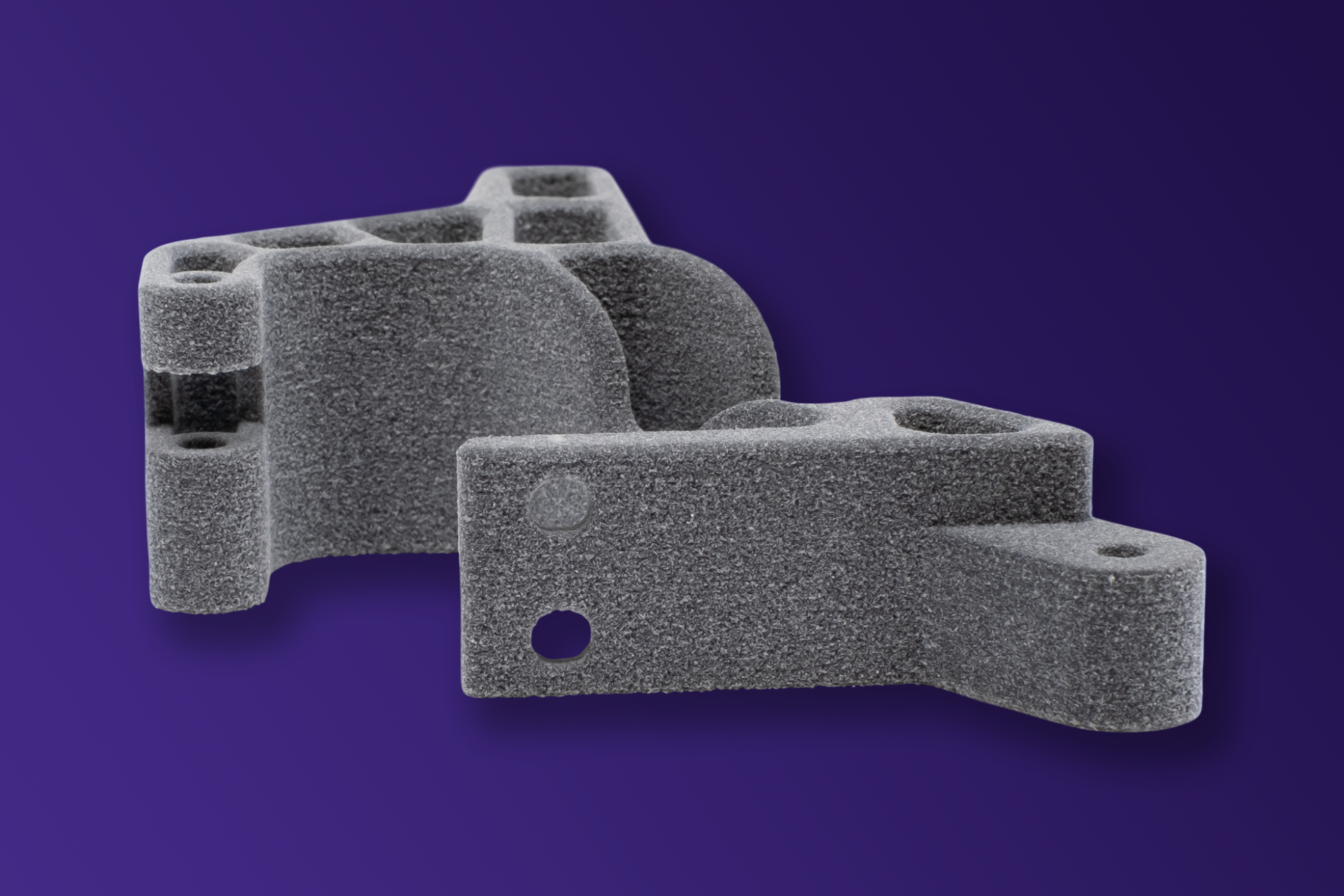

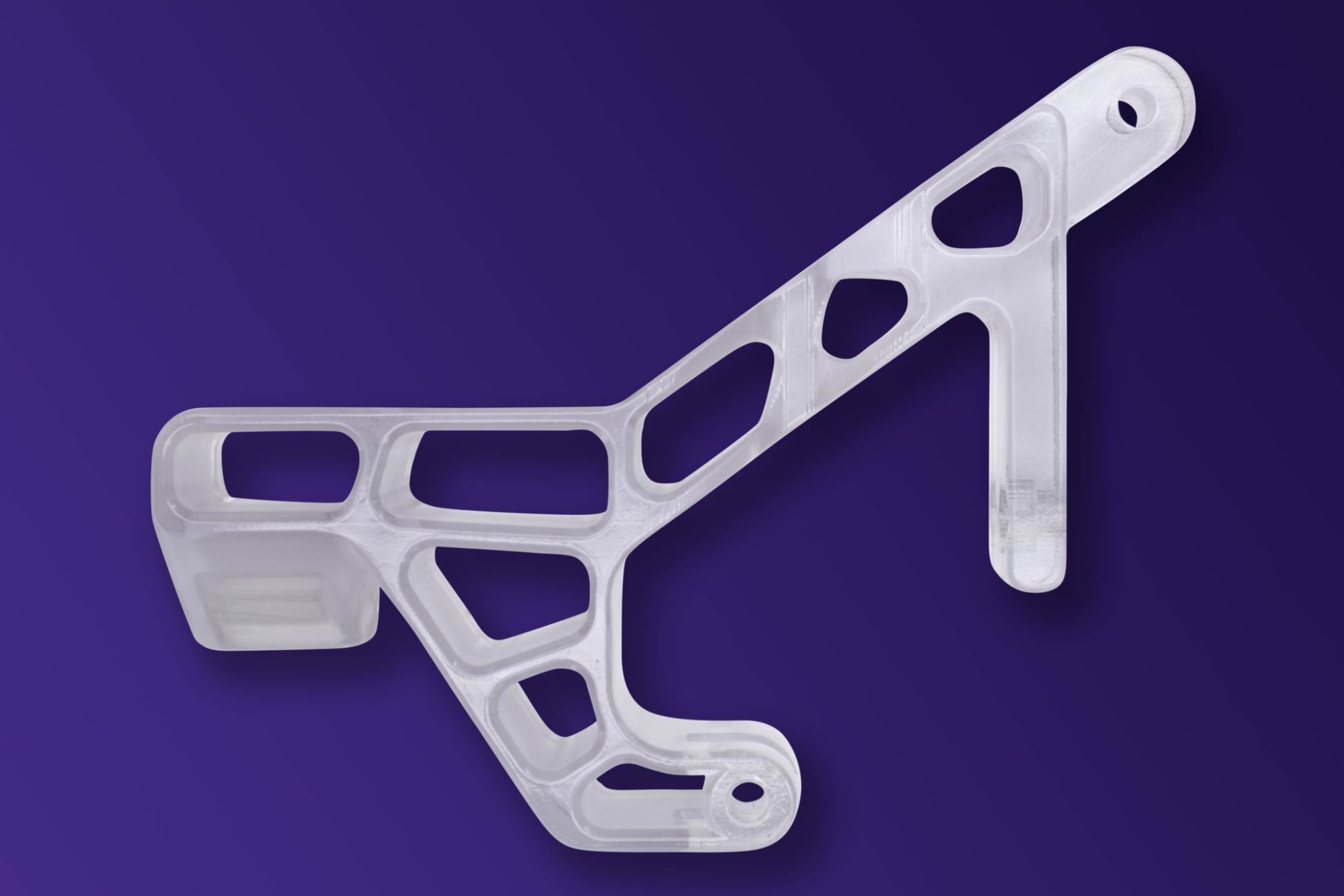

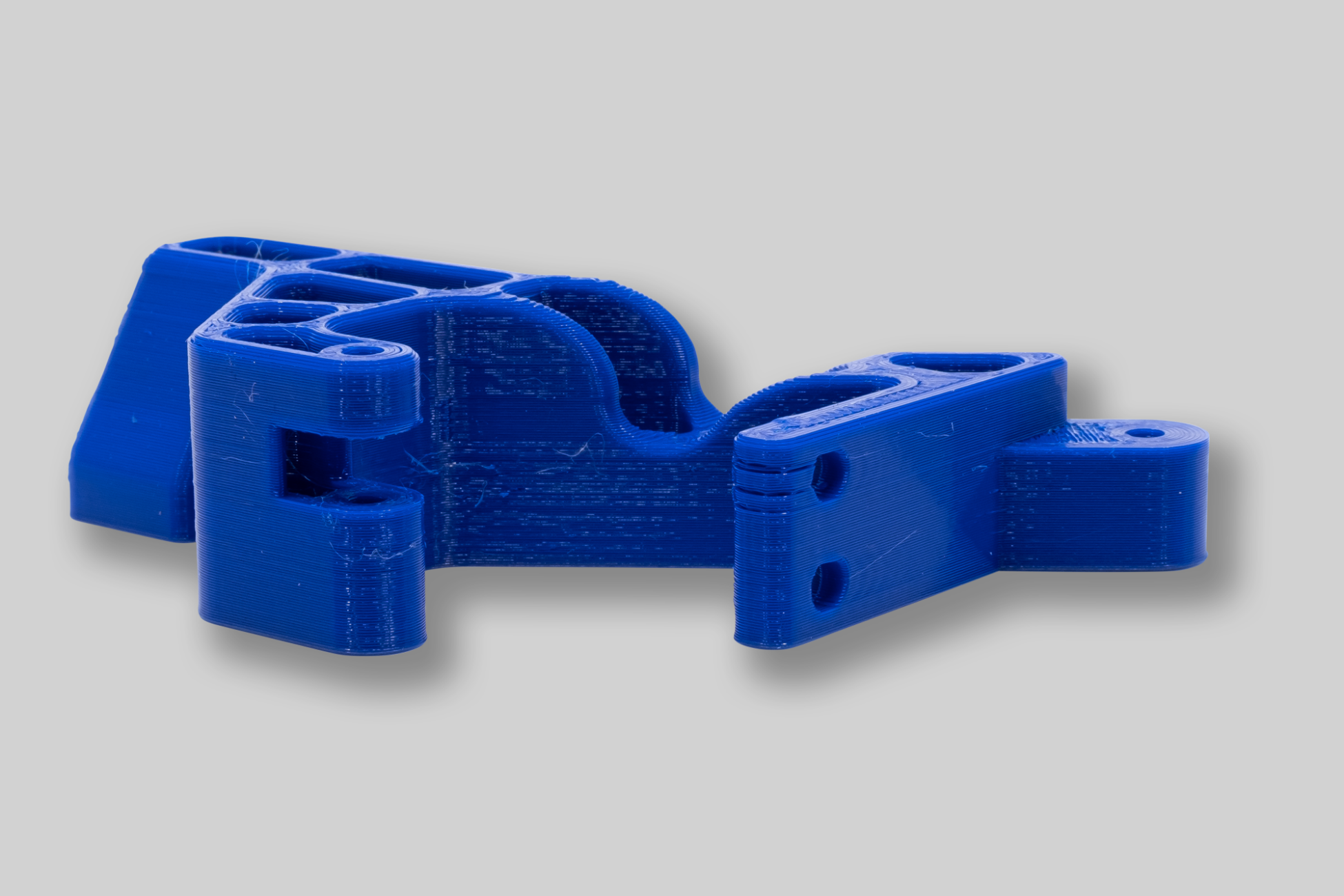

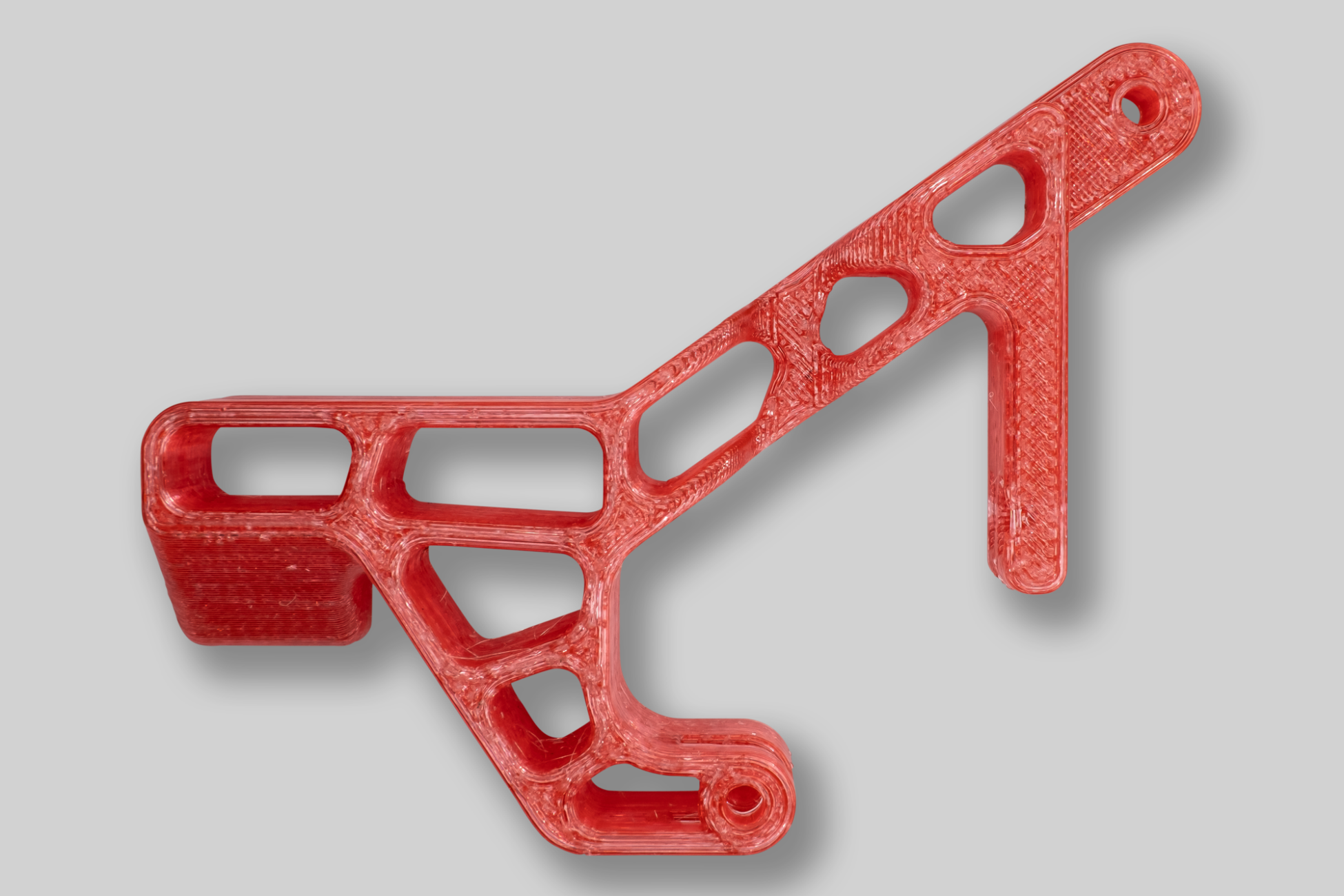

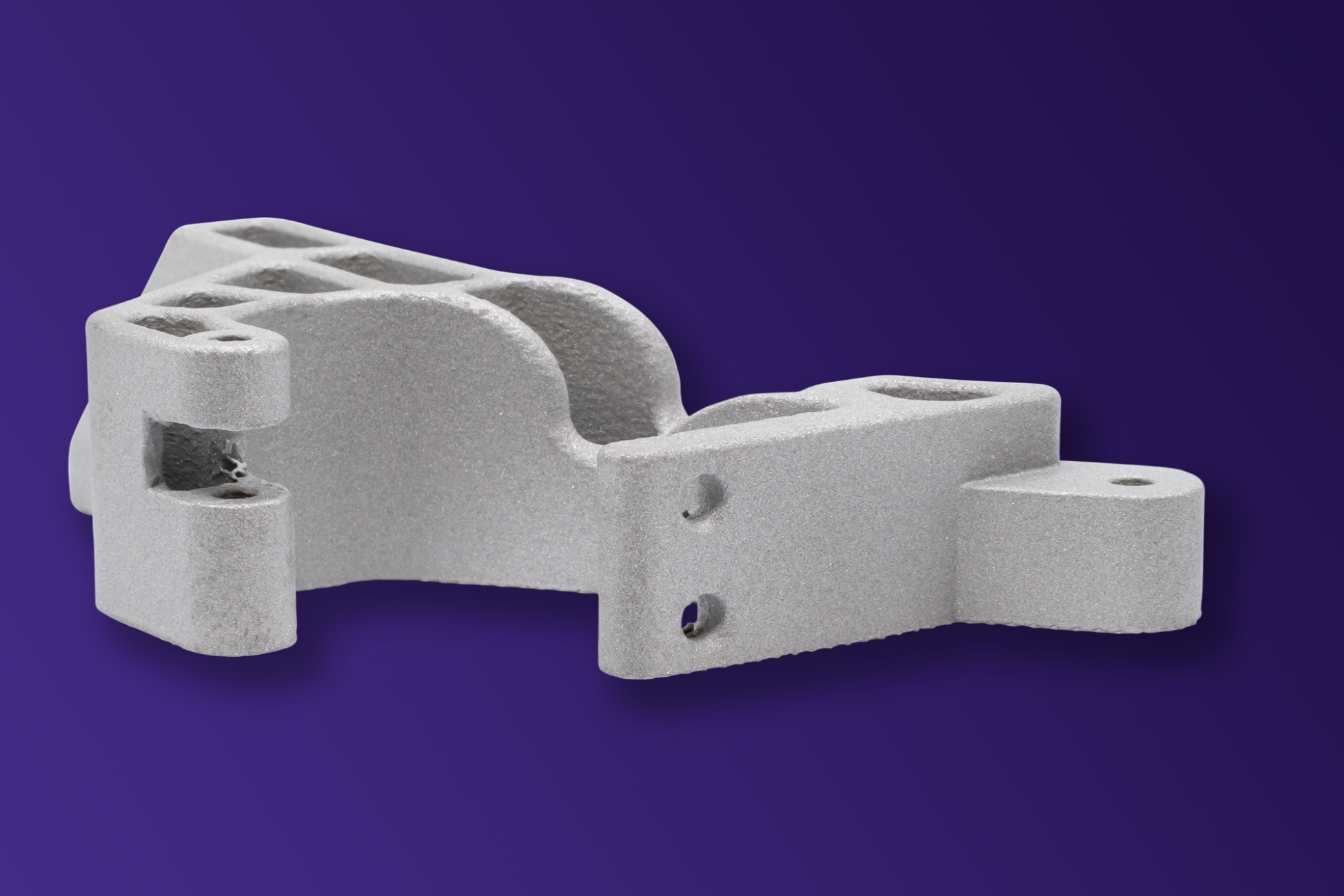

The five most commonly used materials for additively manufactured components are the plastics PA12 (SLS), PA11 (SAF), PLA (FDM) and xCE-black (DLP), as well as the metal aluminum AlSi10 Mg (SLM). These "standard materials" are suitable for most industrial 3D printing projects. In addition, there are a handful of similar materials or suitable post-processings that find application once other properties are required.

First, define the properties that a component must meet. For example, does it need to withstand particularly high pressure or tension? Is it exposed to special temperatures? Does the application need certification, e.g. IS10993 for biocompatibility or food grade? Based on the most important criterion, you can narrow down the material (this is easy to do with the Jellypipe Material Wizard in the Store, for example). Or check first if one of the standard 3D printing materials is suitable, or if there is one of them with an appropriate post-processing.

If you have more than one material that is suitable, or you need an inexpensive prototype, check the price in the store. Alternatively, the delivery time may also play a role, this is immediately visible on the Jellypipe Stores at any time in relation to the price.

In summary:

- Define technical properties

- Check if certification is necessary

- Narrow down the material

- Check material selection in the store

- Make selection

If you are unsure, you can always create an "individual inquiry" on the Store and describe your problem in detail. Or contact the corresponding Solution Partner: Contact Solution Partner